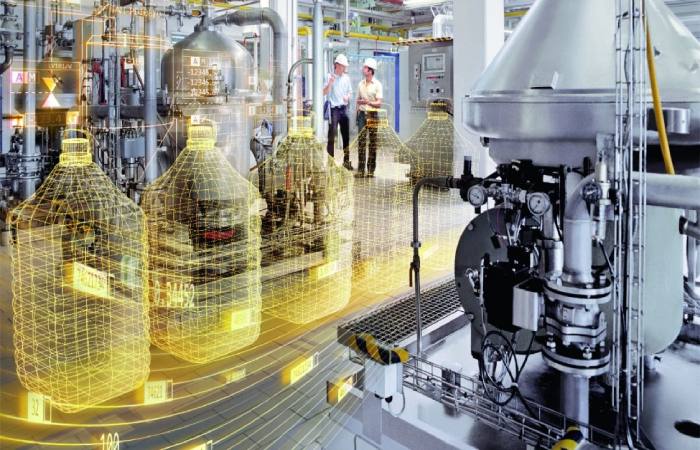

Industrial production process are the sequence of activities require to produce a product. The processes aim to optimize the production objectives (costs, quality, reliability, flexibility). There are several ways to make a product: a material good or service.

The production process is divided into different stages where the inputs involved undergo modifications to obtain a final product with its subsequent placement on the market. The operations carried out are those of design, production and also, distribution. The production system includes the extraction stage, going through the production of the raw material until obtaining the final product.

Table of Contents

Main Stages of the Production Process

The phases of a production process, whether products or services are manufacture, are as follows:

Design

Brainstorming is carry out to capture ideas of how the product will be shape and present. Once the pictures have been decanted, starting from those that remained, sketches of the product are made until the definitive one is finally obtain.

Production

It is the manufacture of the product or defining the service’s details.

Distribution

consists of placing the result of production in the target market. It can be through advertising in the mass media, presentation in shop windows, or specialized and punctually trained vendors, who will visit the other points of sale to promote and exhibit the product.

These phases are use for any production process, although the actions of each product are very different.

Classification of Production Processes

There are several types of the production process: linear or by-product, intermittent or by the project. We explain them below.

1. Linear Process or By Product

It is intend for the production of a particular good or service. The machines involved and also, the amount of raw material used are based on a specific product’s manufacturing requirements. As a single product is manufacture, high levels of production are achieve, for which it is necessary for the personnel involve to acquire high levels of efficiency.

To carry out this procedure, it is necessary to resort to the administration, which aims to maintain the functioning of operations through an effective preventive system, which depends on emergency maintenance that, in turn, allows minimizing the time repair.

2. The Intermittent Process

In this case, the production process is carry out in batches or intermittent intervals organize in work centers where machines with similar characteristics are group. In the process of elaboration, the product will transit, making its way to be control, to the departments or centers that it needs.

Production does not present a regular flow, and also, not all departments of the production system are always use. A great advantage is that a wide variety of products can be produce with slight modifications.

It is vital to have adequate planning and control in each job, knowing when the work orders should start and end.

3. The Process by Project

It is use to produce products that have unique characteristics, such as a house, a boat, or a movie. The production is carry out in a particular place. In this case, there is no flow of the product, but instead, activities are carried out to achieve progress in the construction of the project, avoiding setbacks as much as possible and with good quality.

It is essential to focus the activity on the planning, sequencing and also, control of individual tasks to deal with the different activities best.

Examples of Production Processes

Until now, we have spoken in a very general way, but we will specify by explaining examples of some production processes. We will focus on producing olive oil, wine, beer and also, milk.

Olive Oil Production Process

The olive oil production process consists of 5 phases:

- Collection and transport of olives are carry out from April to June. The olives are occupie in the mill, where the oil is extract.

- Olive washing: cleaning is done with level sensors base on floats. It removes all leaves, branches and weeds.

- Crushing: in this phase, the olive is press to obtain a paste and also, separate the oil from the pulp.

- Extraction of the oil is extract by centrifugation at less than 19º C. In the centrifugation, the three components of the paste are obtained: oil, pomace and also, apelchín.

- Separation of the phases: The three previous components are separate by vertical centrifugation in this stage. The extra virgin oil, the liqui residue (alpenchín) and the solid residue (pomace) are obtaine.

Afterwards, the oil is store in tanks where the temperature is very control and waiting to be bottle.

Milk Production Process

Milk production works as follows:

- On farms, farmers milk the cows twice a day every year.

- The milk is store in refrigeration tanks.

- A tanker truck collects the milk from the farms to take it to the processing companies.

- The milk passes through several filters in the companies and is store in refrigerate silos.

- Subsequently, it receives UHT or pasteurization treatments.

In pasteurization, the milk is heat to about 70ºC for 15-20 seconds and also, cooled to 6ºC. At this temperature, pathogenic microorganisms are eliminate but not their spores. Pasteurize milk must always be kept cold and consume within 3 or 4 days.

The Importance of Defining Production Processes

Quality management systems are present in any company. For a company to comply with quality regulations, it must have procedure manuals detailing all its production processes. Do you have a manual where all your company’s production processes are written. We wait for you to continue talking about the production processes in the comments.

Also Read: What is Philosophical Knowledge? – Characteristics, Examples, and More